Strawbale Walls

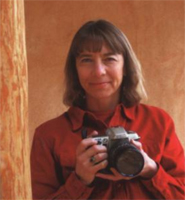

Catherine Wanek After growing up in Las Cruces, NM, Catherine lived in various places until she settled in Los Angeles to work as an assistant director in Hollywood film production. Lured by the beauty of New Mexico, Catherine purchased the Black Range Lodge in the 1980s with a vision of making movies there, and developing the property into a lush permaculture landscape, which now includes an abundance of fruit trees. Since then she has been providing a comfortable respite for others seeking rest and relaxation in a natural, healing environment. After building a straw-bale greenhouse in 1992, she became an advocate of “natural building”, traveling internationally to research and educate, authoring books and videos, and hosting hands-on workshops at the Lodge to spread the word about ecological construction methods. Books she has authored on these subjects include The Hybrid House: Designing with Sun Wind Water and Earth, The Art of Natural Building, and The New Strawbale Home.

Catherine Wanek After growing up in Las Cruces, NM, Catherine lived in various places until she settled in Los Angeles to work as an assistant director in Hollywood film production. Lured by the beauty of New Mexico, Catherine purchased the Black Range Lodge in the 1980s with a vision of making movies there, and developing the property into a lush permaculture landscape, which now includes an abundance of fruit trees. Since then she has been providing a comfortable respite for others seeking rest and relaxation in a natural, healing environment. After building a straw-bale greenhouse in 1992, she became an advocate of “natural building”, traveling internationally to research and educate, authoring books and videos, and hosting hands-on workshops at the Lodge to spread the word about ecological construction methods. Books she has authored on these subjects include The Hybrid House: Designing with Sun Wind Water and Earth, The Art of Natural Building, and The New Strawbale Home.

Questions and Answers

Q: I live in northern Minnesota and I want to build a strawbale home with solar panels on the roof. I would like to know how to enclose the bales so no moisture gets in. I want a basement with a main floor and an upstairs. I got blueprints made up and I am working on detailing them more. I would like the outside of the house to have a log home look to it but I don't know how to enclose it properly.

A: (Owen Geiger)Keep in mind several key points:

- post and beam or some other support system is best in areas with heavy snow loads. In this case, the log cabin would be the supporting structure.

- I see no reason you couldn't build a log cabin and line the inside of it with bales

- solar panels can be put on any style of house, so they're not an issue at all (although, it would be good to plan the pitch of the roof and the orientation to maximize your solar gain)

- never use bales in the basement! Build a wood floor frame and stack the bales on it.

- be sure to allow extra interior space to account for the volume taken up by the bales (you can adjust the walls out 15" or so)

- so... build the log cabin, get the roof on, get your rough electrical and plumbing and heating inspections, and then put the bales in. This avoids hassles with inspectors and ensures your bales stay dry.

Q: Also, what do you use to seal the walls so the straw doesn't rot so bad?

A:(Owen Geiger) The latest paint product being recommended is silicate paint or technically "Silicate Dispersion Paint." This product seals the exterior walls, but still allows for vapor permeability (allows vapor to pass through). There is an article about this in the Spring 2005 issue of The Last Straw Journal. If you're not a subscriber, you should be. One little idea like this can save you thousands of dollars and/or lots of problems. (www.strawhomes.com)

And just to clarify, you said "so the straw doesn't rot so bad?" The straw will not rot if you follow proper building techniques!

Q: I am designing a small (350 sq. ft) home for myself, and I would like to use strawbales on their sides to minimize the thickness of my walls, and therefore my footprint. I am concerned about my ability to 1. notch the bales for posts, 2. shape the window openings, and 3. make little alcoves inside to put stuff on. Are bale houses often built with bales up on their side? or is it a more problematic way to do it?

A:(Owen Geiger) Most people stack the bales flat for the reasons you've pointed out, although you can build with them on edge. You'll need to resolve the details. For example, you may decide to leave the posts exposed (nice design detail). For the windows and doors, you could stop the bales short of the opening and fill the difference with angled framing, mesh, straw stuffing, etc.

Q: I am currently planning to build a unique straw bale cottage which has a base of an isosceles triangle. The problem I am faced with is the bales obviously do not line up at 60 degrees in the corners. I was wondering if it is possible to mark the 60 degree angle on the bale, retie it multiple times along the line and then cut the main line and separate the bale (hopefully being left with a 60 degree angle on one end). Do you think that would work, and if not, do you know of any other way I can get the bales to match at that angle?

A:(Owen Geiger) The maximum angle for retying is about 45 degrees. After that, the twine slips off too easily. But no problem. Strawbale building is very adaptable. Get the corners the best you can and then stuff the difference with loose straw. Another solution is post and beam, where the post takes up most of the corner.

Q: I am building a strawbale courtyard wall around my adobe house in Southwestern CO. What kind of footer or foundation do I need for the fence walls. Someone told me I could use rigid foam instead of digging a trench, is this true?

A: (Jeff Ruppert) I am not clear what you mean by rigid foam for a foundation instead of a trench. What you need to be thinking about is drainage and bearing. A 6-foot high straw bale wall will weigh about 300 pounds per linear foot. If you are in an area with frost heave, you may want to consider taking the foundation below the frost depth. Most of the time, however, we do not do this. We use a simple system consisting of a trench about 10” deep, or through the topsoil. Whatever you do, do not bear any structure on topsoil! We place a ladder made of treated lumber on CMU blocks spaced 4 feet apart. We run straps under the ladder over the wall at two to three foot intervals, and strap the ladders to the blocks. We then fill the trench full of ¾” gravel to the top of the ladders. I know this explanation may not be totally clear, but that’s the simple explanation of what we do. Another issue you may want to be aware of is wind. If the wall will be over 5 feet tall, depending on your location, you may want to create extra corners or buttresses to create stability.

Q: I saw your response for the foundation of a straw bale fence. I was wondering if you would expand on your design of the ladder-cmu block type of foundation and the process of water barrier on the first layer of bales. The way I read your post, The bale wall would be sitting on the ladder at ground level.

A: (Jeff Ruppert) There is no water barrier. There is gravel between the posts as a capillary break. To create a barrier that is vapor impermeable would be too costly for a landscape wall. Over time, the bales will rot and be gone, leaving the skin. Water WILL find it's way in from the top

without a roof. The bales would be a few inches above grade. This can be adjusted with the size of lumber used in the ladder, or how deep you dig the trench.

Q: I live in the 'burbs in Bozeman, MT. We have a fairly large piece of property on a cul de sac that I want to fence with strawbale to replace an existing dog eared cedar fence. My husband thinks it will look too fortress-like. Can you recommend any web-sites or books that contain photos and building instructions for our northern climate? I know instinctively that this is the way to go for our esthetic and privacy needs, but he is skeptical!

A (Kelly): I might caution you that many folks experienced with strawbale building do not recommend the use of bales for fences because it is too hard to keep them dry, so they will eventually decompose. I did a little searching on some of my strawbale links and came up with this resource: How to Build Straw Bale Landscape & Privacy Walls by Tim Farrant.

Q: I live in Perth, Western Australia, where the climate is hot and dry. Straw bale structures do well here. My question is about a possible internal retrofit (for insulation) to my 56 square meter workshop which is concrete floored and steel framed and clad with zincalum metal siding which makes it unusable on any day over 25 degrees Celsius. Can I place bales against the siding without rendering them first or will this create condensation problems? Any suggestions would be greatly appreciated!

A: (Jeff Ruppert) I would suggest dipping the side of the bales that will be against the siding in plaster when you are placing them. You can also stuff any voids with a cob type of mix. The trick is to eliminate any air pockets. These pockets will reduce the energy efficiency of the bale insulation and it will also keep any rodents and bugs out. It will also help with fire resistance. The trick to bale building is making sure all of the bale wall surfaces are covered with plaster. If you need more help, try the Australia Straw Bale Building Association at: http://www.ausbale.org/ .

Q: Is it possible to cover the sides of a strawbale wall with wood siding over a layer of stucco, with no space in between? The climate here is similar to New Jersey, slightly damper at times.

A: (Jeff Ruppert) Yes, it is possible. You would actually want a small space to keep any water draining on the inside of the siding down and out without touching the plaster. I would suggest two rough base coats under the siding.

Q: Has standard drywall/gypsum board been used in conjunction with strawbale construction. I am a Yale architecture student currently collaborating with the first year March class on the building project. We are designing and constructing a house to be completed this summer. Given the greater skill required to provide a hand troweled plaster finish, we are hoping to use standard 4x8 drywall panels to finish the interior of the house while still using strawbale as a primary building block.

A: (Jeff Ruppert) Yes, this has been done. However, you will need to apply at least one base coat of plaster, maybe two depending on structural requirements. This is for fire, insulation performance, moisture, critters, etc. To install drywall you will need to attach 2x sleepers to the wall. Once the sleepers are installed, you will apply your plaster in a rough fashion between the sleepers, leaving at least a 1/2" gap to the face of the sleepers. Upon the completion of plastering, you then install your drywall onto the sleepers. This is also the way to use siding on the exterior.

Q: Is there a big difference in using hay or straw? We have a more abundant supply of hay. Would it make a difference to use it instead in a northern Minnesotan home? I would also like to build my barn that way too.

A: (Owen Geiger) Hay is intended for livestock and contains green leafy matter. Straw comes from the dry stalks of cereal grains and has no nutritive value. The pioneers in western Nebraska successfully built houses out of meadow grass, but hay in general is not recommended. It is more prone to rot and decomposing, could attract rodents and insects, usually costs more and probably doesn't have as high an insulation level as straw. I highly recommend looking harder for straw. Look for farmers growing cereal grains. Or ask straw bale builders in your area where they get their bales. Builders and architects can be located in the Fall Resource issue of The Last Straw: http://www.thelaststraw.org/

Q: We have a house that borders a highway and are thinking about building a Straw Bale privacy fence to block out sound and sight. My question is, do the bales come treated and if not, how do we construct a fence without the straw rotting from adverse weather conditions? Are there any websites that show how to construct a wall/fence out of straw bale?

A:(Owen Geiger) Many or most strawbale privacy walls are beginning to experience moisture problems. They are marginally suitable in very dry climates as long as you add a protective cap on top such as roofing tiles. The problems result from a lack of moisture protection. (For instance, a properly designed strawbale house will have wide protective roof overhangs.)

I recommend using either earthbags or cob for privacy walls. Stone is another good choice, but it's quite labor intensive. Earthbags are a logical choice -- they were invented for flood control, and as long as you protect them from sunlight, they should last a very long time. One technique involves using earthbags below grade as the foundation.

Q: I'm considering using strawbale as an infill on a Timber frame. When I asked the timber framer expert what framing system he would recommend, he asked me what would happen if any of the seeds germinated in the bales? Considering the dampness of the west coast and the lack of vapor barrier needed in strawbale construction, I thought it was a question I should try to answer.

A:(Owen Geiger) Strawbale buildings have been built in every state (including very rainy climates) except maybe Hawaii, as well as many countries. You won't have any problem as long as you provide an adequate roof overhang, raise the bales far enough above grade, and detail window and door openings correctly. Do not add a moisture barrier that prevents the flow of vapor through the walls.

Q: Help! I'm building a straw bale building in South Africa and have located some oat straw from which the oats have been harvested. The straw has been lying on the ground for about three months and is 90% golden, with some smaller stems having black on them [mold?]. Is this suitable to bale and build with?

A:(Owen Geiger) This is a judgment call you will have to make. The black straw you describe is covered with mold and can spread if enough moisture is present in the wall. On the other hand, if housing is urgently needed, the building is properly designed to reduce risk of moisture damage, and this is the best straw you can get ... then maybe it's worth it. Once plastered, the mold will probably not spread because sufficient moisture will not be present.

Q: We are considering building a straw bale home and was wondering if using papercrete would be a good stucco agent for the brown and scratch coats both inside and out, but only after the initial clay slip coat. The final coats would be a lime/clay finish.

A:(Owen Geiger) I see no reason why you couldn't use papercrete. However, earthen plaster is simpler to do and less labor intensive. You don't have to make or buy a special mixer, gather the newspapers, etc. It's also faster to mix earthen plaster than papercrete. And, there's no need to add cement to earthen plaster -- it's just mud. This means you can use your bare hands and not worry about your skin or splashing cement in your eyes.

Q: For a post and beam bale wrap, we were planning to place bales on edge to increase floor space, but are being advised to place bales flat, to simplify construction, specifically to ease notching for 2-string bales around window/door framing. We're attempting to size framing to bale size where possible, but realize there is always a need for some notching. What's your suggestion for bale orientation in this case. We are in Vermont.

A:(Owen Geiger) I prefer stacking bales flat. It's easier and the walls are more stable during construction. Sometimes the plaster will bond better this way. Also, it's easier to add nichos, etc. Consider leaving the posts exposed: it's more aesthetically pleasing and you save many hours of notching. Just stack the bales to the outside or the inside of the posts. (Of course, the original design must take this into account.) I'd put the posts on the inside so I could enjoy the beauty of the wood.

Q: I live in Taos NM.... and am interested in a strawbale fence. In Albuquerque they tamped the ground with a jackit and then laid a layer of plastic and put the strawbales right on top of it, running rebar through and plastering the outside finish. Do you think this would work here in Taos??? Your ladder idea puts wood on the ground and I was concerned with dry rot. What if you tamped the ground and then put a layer of pea gravel and then plastic and bales.... wrapping the bottom bale completely in plastic and bringing 5-8 inches of it over the top and placing the next bale on top of that. This way you would still have breathability, but a vapor barrier toward the ground. Also, I was thinking of a cement cap on top before the plastering. This will be 3-4 bales High.

A:(Owen Geiger) The system described by Jeff Ruppert, an experienced engineer in Colorado, raises the ladder and bales above grade. The wood is not "on the ground," it's raised on concrete blocks. I'm not a big fan of strawbale walls. Reports from the field are showing widespread failure. Straw bales need a roof to protect them from moisture damage, and unless you add some kind of protective cap on top (roofing tiles, etc.) then you'll probably have moisture problems sooner or later. And finally, your idea puts the bales right at grade, creating a greater risk of moisture damage near the ground. Not a good idea.

Q: I live in Noosa, on the Queensland coast of Australia, on a beautiful acreage property and wooden stilt home. However, our peaceful life is being spoilt by a great number of sand trucks that now pass our property to and from a quarry that has been opened. As on some days there is an excess of 300 trucks a day, we are desperate to eradicate this noise and regain our sanity. I would love to know your thoughts on whether a straw bale fence would be a viable material to use. The fence will have to be 130m at the front alone and 2m high. I am assuming that straw would be a good sound barrier, but am concerned about using it in a bush fire risk area (though there haven't been fires locally here for a very long time). Once in place and plastered (or whatever finish you recommend) would it still pose a risk or is there a way of making it fire retardant? We have monsoon weather some years and can have large rainfalls with flash flooding, but as long as the footings were sound, would it still be viable?

A:(Owen Geiger) How well insulated is your home? It sounds like you need home insulation and a privacy wall. But strawbale privacy walls have a mixed reputation -- those without an adequate protective cover on top are failing from moisture damage. In a monsoon region, you'd be taking a sizable risk.

I recommend carefully insulating the home with thick insulation (such as bales) and building a high privacy wall using materials that won't rot. As much as possible, use materials that are locally available - stone, earthbags filled with aggregate/soil, etc. Also, add fast growing trees to help buffer noise.

Q: Once inside our house the noise level is fine, the problem is that we are unable to enjoy our land once outside or sit and relax on our verandah. The road is higher than the level of our garden as it falls to a creek that wraps the house. This is why we need to build a sound barrier between us and the road, but as the fencing needed is so great (130m at the front alone) I have major issue with using wood as it is at such an environmental cost. We have investigated block walls etc but am sure that they will reverb the noise rather than absorb it. If well constructed are there ways of successfully waterproofing the straw and if so, would it still screen the noise?

A:(Owen Geiger) Strawbale acoustical tests show bales do excel at dampening noise and for your situation it may be the best option. You'll want to 1. raise the bales well above the flood line/splash level, 2. add a protective cap of roofing tiles (or equivalent) on top, 3. protect the bales with a crack-free, curable plaster (hairline cracks are acceptable). Check the plaster periodically and seal any cracks that may develop. Additionally, add some curves or buttressing to strengthen the wall.

Q: I want to build a load-bearing straw bale home. I will not have lots of money or lots of help. I hoped you could help me with the details of constructing segments of the walls in a prefab manner. That way maybe I could do most of it myself accept for moving the walls in place.

A:(Owen Geiger) Prefab panels lend themselves to larger projects, especially where standard panels can be used repeatedly. For small projects, it's hard to beat the efficiency of just stacking the bales. The walls of a 1,000 square house can be stacked in one day. You'd need to rent a crane to move panels, while bales can be stacked by one person.

My major concern with having no help, is the amount of time plastering would take or even be possible alone.

Plastering: Have one or more weekend "plastering parties" with friends and neighbors -- provide pizza, BBQ, drinks, etc. You will need help. The first 1-2 coats can be done by volunteers. However, you may want to get a skilled plastering crew for the final coat for the best protection and looks.

Time concern: There's no free lunch. Building a house is very time consuming no matter how you do it. Pre-fab may save some time on the plastering, but there are offsetting costs and factors to weigh in (like renting a crane). That said, there are some techniques that are more efficient than others, but it's still lots of work. My approach: simpler is better. Design a small simple house and stack the bales.

Q: I would prefer to lay the bales flat for the higher R-factor. Can plans be modified accordingly?

A: (Kelly) I suspect that the plan can accommodate either orientation of the bales...however, it is my understanding that the insulation value of the bales is nearly the same in either case, because when the bales are flat the straw tubes run from inside to outside, whereas on end, the straw ends are not exposed to the skin of the wall.

Q: Can you think of any real reason not to build a load-bearing strawbale house from the very large commercial straw bales? It is my intention to do so, and then do all the interior walls in cob for thermal storage. Was actually considering compressed earth blocks as an interior and exterior finish material....any thoughts?

A: (Kelly) I know somebody (Sun Ray Kelly) who actually did build a home with those enormous bales and I saw a slide show of the process. They were set into place with a crane. It seems to me like a bit of overkill to do this, not only because of the effort in transporting and placing the bales, but also because the added insulation is unnecessary; ordinary strawbales provide plenty of insulation. Also good standard 3-string bales do fine in load-bearing applications. Of course with such large bales, you would also need to provide a massive foundation and loose all of that potential floor space to the thickness of the walls.

Either cob or compressed earth blocks should do fine for an interior finish. For exterior, these materials might do better with a lime render or such. The compressed earth blocks are susceptible to "blooming" if they get wet, so this should be taken into consideration.

Q: After extensive research online, hours of reading, and more hours refining plans, my husband and I are planning to build a cordwood/strawbale house. We are planning to pour a footer that is wide enough to accommodate a single cord-wood wall, and then butt strawbales up against it. I don't know if anyone has attempted this before, and was wondering if you thought we should use spray-foam sealant on the inside of the cordwood wall, or a vapor barrier between the cordwood and straw bale. We are planning to fill-in post and beam construction. I know that many of the strawbale sites don't advocate a vapor barrier, and thought maybe the foam sealant may be the way to go.

A:(Owen Geiger) A double wall of strawbales and cordwood is extreme overkill. You would end up with a wall about 36" thick that would waste considerable floor space, time, money and labor. Either one is sufficient. My preference is strawbale, due to it's speed, ease of construction and high insulation value.

One option: Use cordwood on the lower courses -- say, the first 24" - 36" or so, and stack bales on top. This would raise the bales above snow line/splash line and add some beautiful wood into the design. Plan ahead so the finished wall surfaces meet correctly. (The cordwood should be long enough to account for the plaster on the bales.)

Sealing air gaps to prevent infiltration is important, but never use anything that will seal off moisture from passing through the walls. This is true for cordwood and strawbale.

Q: I'm looking at open steel or pole barn for the load bearing part. Ton bale exterior, standard bale interior walls in the sleeping areas all else steel stud and sheetrock. All the electrical will be in floor or in conduit as well as the heating. Suspended ceilings in some areas, vaulted in others. The finished product will put no loads on the walls.

A:(Owen Geiger) "Ton bales" - Once you get beyond 18"-24" insulated walls, there's a point of diminishing returns. Massive walls are not that much more energy efficient, but do consume a great deal of space and waste resources (extra roof materials, etc.) Also, plan carefully for day lighting. Less light will penetrate the deep openings and your windows may look strange with extreme insets. (Small windows will look like tunnels.)

Q: What other options are there than plaster?

A: I recommend earth plaster for it's low embodied energy, cost, ease of application, low toxicity and amazing aesthetics. You can use anything that doesn't block the transfer of moisture -- wood, bamboo, etc.

Q: We are working on a post-and-beam strawbale home, and I am curious at what point the drywall is installed. Do we need to have it installed after the first coat or second coat of plaster?

A:(Owen Geiger) Drywall is not needed and requires extra effort to install nailers. You'll also lose some of the charm of a handcrafted home that comes from slightly undulating surfaces. Hard rectilinear surfaces just don't feel the same. I highly recommend earth plaster. Before you decide, get 1-2 good books on earth plaster to see how beautiful the results can be.

If you decide to use drywall anyway, tie 1x4's to the bales about 16" to 24" apart. (Did you lay twine between each row of bales to do this? If not, use a bale needle.) Don't forget to stuff the gaps with an earth/straw mix. Then add a coat of earth plaster to help protect the walls. Use drywall screws to hang the drywall.

Alternative method for bales stacked "on edge": slide the 1x4 nailers under the twine that holds the bales together.

Q: We have an Inn in Joshua Tree, CA and though we are set back from the road, we have a lot of road noise. We have a chain link fence around the property on which we have planted Oleander on the highway side, but we want to put up a straw bale wall on the inside. Should it be at the fence or further back toward the buildings where the land is higher.

A:(Owen Geiger) I'm advising people not to use bales for privacy walls. Sooner or later moisture will probably find a way in and damage the bales. Earthbags serve the same purpose and are much more resistant to moisture damage. Just keep them tarped during construction or plaster the wall immediately to prevent ultraviolet damage. Locate the wall where you think best. Consider all the factors, not just road noise, but also aesthetics, privacy, wind, future building plans, etc.

Q: You said, "it really depends on whether you can source high enough quality strawbales." Can you evaluate the quality offered by these people?

A: (Kelly) It is kind of hard to evaluate strawbales without physically kicking them and checking them out. Basically you want tight bales rather than loose, floppy ones, for solid construction. Obviously you also want bales that show no sign of rot or deterioration, and a bright golden color throughout is a good sign of this. The pictures on their website show two-string bales, which are often smaller and less compacted than three-string bales...so you would need to check them carefully to see how good they really are. It would seem to me that if they have been using these bales successfully in a variety of projects, then you are reasonably safe to use them as well.

Q: I would like the benefits of a super-insulated house, like strawbale, but have access to wood finishing products for interior and exterior, which seems would be easier and faster to cover the straw bales. Can this be done effectively, and would you have suggestions as to how?

A:(Owen Geiger) What do you mean by wood finishing products? Paneling, wood trim, etc.? That's fine. Bale walls can be sided with wood. One trick is attaching nailers to the bales so they are all in the same plane. Above all, do not put a plastic moisture barrier on the wall. Allow moisture to pass through. Also, I recommend spraying the bales with a coat of clay before covering them with wood. A rented drywall texture gun or the equivalent is one fast method.

C: What I mean is cedar paneling -- 1x8x8 ship lap or similar stuff, inside and out, probably horizontal on the outside, vertical on the inside. So far, it seems many think it's important, as you said, to encapsulate the bales with plaster of some sort, to prevent rodent infestation, and one indicated that it was important to keep the wood off the bales, but to do so could create an air space that would be like a chimney effect in case of fire -- thus accelerating the fire. Anyway, I do have sand and clay nearby, and a friend who may be able to provide something that could shoot it on. From there, for me, for a finish look, wood is faster. It's going on to the back of a log cabin.

A:(Owen Geiger) 1x8 paneling will work great and look good too. And being the carpenter type versus a plasterer, that's how I'd be inclined to go. A small 1/4" gap or so behind the paneling is OK. A small gap of this size on the exterior would allow any condensation to drip down and out of the wall. A large gap of 3/4" or more would start a chimney effect as you've pointed out. Also note, coating the bales with earth plaster will reduce flammability, mold and insect problems.

Q: I am going to be constructing a small building to use as and office/studio and I would love to insulate with bales. The problem is, the building must be somewhat portable and I know stucco will crack with the racking and shaking during transportation. Have you ever heard of anyone covering bales with OSB sheeting, tyvek and siding for the exterior (providing a vent along the top of the wall), and sheetrocking the interior, as in conventional construction?

A:(Owen Geiger) This is certainly possible, although not common. One drawback is bales take up a lot of space on small structures like this. I wouldn't spend money on tyvek. No real need if you have adequate overhangs, etc. as you should anyway.

Q: I am looking at putting up regular 2x4 walls at 16 in on center then covering the outside part of the wall with plywood and then placing the straw wall up against the other side of the 2x4s, then filling the cavities in the middle with concrete that would seal the inside area of the straw stopping moisture from getting to it and any fire hazards as well as giving me way to attach siding and a supporting wall that can't settle for my second story to rest on, as well as allowing me to maintain level for the next story. On the inside I am going to coat the walls with plaster like they say to do.

A:(Owen Geiger) This doesn't sound very good to me. It's very much overkill. You're using three wall building systems, two of which are energy and resource intensive. There are much easier, simpler ways of building which are clearly described in the best books and The Last Straw Journal. I strongly advise doing more research and simplifying the design.

Q: I have an old wood frame (2x4) and stucco home about 1450 square feet. I would like to start adding strawbale walls to the exterior, with as little change as possible to the frame of stucco in doing so. I should also say that the house is surrounded with concrete extending about 3' from the side of the house, rising about 2" above the soil surrounding, perhaps slightly sloping away. The house is built on concrete piers with crawl space. It is probably 40 years old. I expect to add a metal roof, as well, and will allow extra overhang.

1)How should I fix the bales to the house? Reading your website, I think I will stack them on edge.

2)Will frost heave likely be a problem in this relatively dry climate? Or could I just level the concrete already in place and start stacking?

3)Do I need the vertical rebar pins if it's tied to the frame of the house?

A:(Owen Geiger) Adding bales to the outside of your home is a good way to add insulation. And with concrete surrounding your house, it will be relatively easy to do. Building the roof first will provide a shady space for working and protect the bales from moisture damage. Extend the roof about 3' beyond the bales. This is easy to do with pre-built trusses, which also creates space above the house for roof insulation.

You'll need to raise the bales off the concrete to prevent wicking. One common method is to fasten wood 2x4's (laid flat) to build a "toe-up." The space in the middle can be filled with perlite, gravel, scoria, etc.

Rebar pins are not needed and no longer used. Attaching bales to the stucco wall: Browse a large home building supply center for various kinds of masonry anchors. Depending on the system, you'll probably have to buy one or two high quality masonry drill bits. You could rent a heavy duty drill for the weekend very cheaply. A hammer drill will speed things up even more. Then it's just a matter of tying poly twine through the anchors to the twine around the bales. Each bale will require two anchors.

Stacking bales on edge requires fewer bales, takes up less space, is faster, and you don't lose any insulation value due to the orientation of the straw.

Frost heave: Does the concrete around the house have large cracks? If so, then the soil is heaving. If not, you're good to go. Leveling the concrete: Actually, you'll level the 2x4's as you install them. Add tarpaper under the wood to prevent wicking.

Q: Can we build slanting walls using strawbales? If yes, can you suggest techniques?

A (Kelly): I have seen strawbale vaults with slanting walls, and I believe that they were built over a form. In general slanting a strawbale wall is not advised, because it is too easy for it to become unstable.

Q: I am interested to know if a strawbale house using cob around the bales would do the trick for insulation in cold, wet climates where mold and mildew can be such a problem. I understand that homes hundreds of year old in England often protect the cob with a stucco cover or some such mix for wind damage as well. I'm thinking one foot Cob on outside and inside of each bale, with a couple of inches - or even less if you recommend - on each side, to seal it? So, what would the structural, insulation, moisture issues be in a cobbed strawbale situation; and would it be easier to pass inspection? Any other creative ideas?

A:(Owen Geiger) Your plan is very labor and time consuming, and also massive walls take up a lot of space. I suggest earth plastered straw bale walls with possibly thicker than average plaster on the interior to create extra mass. Wide roof overhangs (about 36") or even wrap around porches will keep water away from the walls. Raise the bales well above grade to keep them dry. Choose a roofing material that isn't likely to leak.

Q: Is it possible to cover the exterior wall of a strawbale building in traditional clay bricks? I want to build a house that looks conventional on the outside, but performs like a straw bale home in all other aspects.

A:(Owen Geiger) This is not common and so there's very few houses to base an opinion on. I'd say it's okay if you follow a few steps. Plaster the exterior of the bales with clay slip. Leave a small gap (1/4"-1/2") between the bales and bricks. Provide weep holes at the bottom so any moisture can drain out. Add high quality fans in rooms that produce excess moisture (kitchen, baths, laundry). Also, I wouldn't attempt this in a high humidity area.

Q: I understand that strawbale walls are problematic because they decompose. I'm considering building a 4 foot high wall and not providing any covering for it. I live in Rochester NY where it is very moist and I thought that the wall would look very nice covered in plants and moss. If the bales are tight, wall is 2 feet thick, and I secure it by pounding steel rods downward through the overlapping bales, how long do you imagine that the wall would take to break down to the point that it becomes unstable or unsafe? Given a 2 foot deep footing with a gravel bed and surround, how much do you think the longevity would change if the footing was strawbales vs. concrete?

A:(Owen Geiger)

First of all, bale walls are not problematic if they are protected with a roof. Bale houses in Nebraska are over 100 years old. But left exposed outside, they will decompose very rapidly. I made a raised bed garden with bales in a dry climate and they were 50% decomposed in about two years. Raised above grade in a dry climate, they should last a little longer. But in a wet climate ... well, why bother? I recommend plastered earthbag walls for much more durability. No concrete foundation is necessary if lower earthbags are filled with gravel.

Q:

I have been looking and wanting to buy the plans for a straw bale house. My only question is inside the walls what keeps the roof from compressing them over the years and what holds it down during wind storms? It appears the bales would compress over time. I understand both inside and outside will be covered with plaster or cement.

A: (Kelly) There are two basic ways that strawbale buildings deal with compression from roof loads: load-bearing and non-load-bearing. In load-bearing buildings, the bales do hold up the roof and they are usually pre-compressed with tensioned straps that loop around the entire wall, including a top plate and sill, so that no further compression is expected. In non-load-bearing systems, posts and beams carry the load and the bales are essentially infill. In either case, the roof is tied to the wall through conventional connectors between the rafters or trusses and the top plate.

Q: Can strawbale construction be used for 4' retaining walls in Klamath Falls, Oregon?

A:(Owen Geiger) I would advise against it. There's too much rain. Sooner or later water will find a way in through cracks and rot the bales. You can get the same effect with earthbags stabilized with lime (although it takes more effort).

Q: We operate a Tibetan Buddhist printing press in Northern CA., generating 72" x 36" x 30", 1400 lb bales of compressed trim from the books. We are interested in building storage buildings in straw bale technique instead of shipping bales to recyclers. Do you have contacts or know of anyone working with paper bales?

A:(Owen Geiger) I don't have any direct contacts, sorry. But I believe this will work. It's practically the same as strawbale. The bales are overly large for houses, but practical for storage buildings. Two sources: Search back issues of the The Last Straw journal. I can't remember if what I've read was in TLS or on the web.

Q: I am interested in strawbale construction, however after living in stucco-covered masonry buildings for almost two years I have grown to like wood a whole lot more. How might I be able to construct a straw bale house using mainly wood for structure and finish?

A:(Owen Geiger)

Stucco and concrete block are made of cement and they create very uncomfortable, unnatural buildings. Have you lived in a house of earth plaster? They're wonderful. The acoustics, feel, etc. are very different -- very warm, soft, quiet. That said, you can use wood paneling, siding, wainscoting, trim, etc. We built a straw bale house for Habitat for Humanity using wood siding that was indistinguishable from similar houses in the neighborhood. (We wanted it to blend in.)

Vertical 2x2 furring can be added on top of the bale wall so the siding etc. has something to attach to. A good straw bale book should cover this. They're fastened to the toe-up at the bottom (which raises the bales above the risk of water damage) and to the bond beam along the top. Twine ties would stabilize the middle part. Screws or nail guns (which can be rented cheaply) are recommended since the 2x2's will tend to bounce. Using 2x2's like this also makes it easier to install cabinets, electrical and, to some extent, plumbing. (Never run plumbing through bales walls.) Also, it's a good idea to coat bale walls with clay slip before adding the furring strips. This increases fire protection and moisture resistance.

Q: I am in the process of purchasing a straw bale home near Edmonton Alberta, Canada. I have taken courses locally and read extensively. Most buildings in the area, including the prospective purchase, have concrete stucco on both sides. My limited training suggests mesh on both sides of a load bearing straw bale wall. Today I got a reply from the seller/builder's realtor as follows. "70 lbs of spray 1st coat goes right into the bales (there are 3 coats all together). The curve on the windows are rounded with standard stucco mesh. The way he (the seller) explained it to me (the realtor) was that there is no mesh wire on outside of home as this weakens the bales This is how the bales are tied to the foundation - A 2x4 "ladder" hooks to the foundation, then the bales go on top of ladder then they are super sprayed & this ties to the foundation." Is this one side mesh method viable?

A:(Owen Geiger) Tests and anecdotal evidence suggest mesh is not required on straw bale walls. Many builders use it only around window and door openings and exterior corners. Spraying stucco will force the plaster into the fibers, that's true. This adds a lot of strength since it bonds the straw and plaster. I don't think mesh would weaken the plaster if everything was applied correctly. One side with mesh is also okay. So there are numerous methods that work.

Q: I am very fascinated with Simon Dale's house (www.simondale.net) which he built for some 4,500-5,000 U$. He has photos of the building process including plans on his site for reference. I would like to copy this house, though I am unsure about the roof and the floor regarding soundness of design. Could you please advise and also advise how long such a house might endure given that form of construction?

A:(Owen Geiger) I've studied this house in detail and know how to make it faster, better and more durable. For instance, he used straw bales against an earth berm, which is not good building practice. I would use scoria-filled earthbags. The hardest part will be doing the roof. Are you sure you want to build the same way?

I am sorry, but there is definitely not a chance at all to getting a building permission for an earthbag-wall/home in Germany. Straw bales are allowed, earthbags are for building emergency dams over here. I wasn't planning on setting the house into a hillock. That's why I asked about floor and roof. Dale's floor structure appears to be for the floor: compacted rubble and sand; dry wall foundations for the walls/flat; stones for posts; plastic sheet against the rising damp; wood pallets; strawbales; wood pallets; flooring. And his roof has: canvas; strawbales; plastic sheeting against roots and water; earth; grass.

(Kelly): I would not advise you to duplicate very much about this specific design in way the materials were used, in particular the use of straw under the floor and as part of the roof or in a bermed wall. The reason for this is that straw really needs to be able to breathe on both sides in order to expect it to be stable over time. Otherwise there is too much risk of the straw getting damp for for some reason and not being able to dry out sufficiently, and therefore rotting. When straw is covered on one side with a moisture barrier, this provides a perfect place for condensation to form under certain circumstances, so then you have the moisture problem.

The secondary comment about what the German authorities would or would not allow, we can't really know. I know that as designed, the Simon Dale house would not pass code in most places on the United States, for multiple reasons. I love the basic design of this house and the way it looks, and you should be able to find ways to adapt the concept to suit both your needs and those of the authorities. I would say that a house similar to Simon's house could last a very long time, especially if the strawbales are not compromised by being located in a bermed situation. If it were well built, with proper attention to the details of maintaining a good foundation and having adequate roof eaves to protect the walls, it should last a person's lifetime at least.

Q: We are going to build several straw bale buildings as vacation rentals on 17 acres in Ruidoso, NM. One of the biggest hurdles, and I would not have expected that, is to find a affordable source of 3-string straw bales. Can you guys help me out there?

A:(Owen Geiger) Bill Christensen of Sustainable Sources maintains the largest list of straw bale suppliers. You'll have to Google to locate the address or go through The Last Straw Journal. 3-string bales are quite rare in your area. I would go with 2-string bales for greater selection, lower cost and less shipping. Once you get above a certain amount of insulation, which you do get in 2-string bales, then it becomes overkill. You won't lose energy through the walls, it will leak through windows and doors, etc. (path of least resistance). The best bales come from Albert Francis of Alamosa, Colorado. He's supplied builder quality bales to the majority of the houses in the four state region. His bales are far above typical farm quality bales.

Q: I have a 30 yr old double wide 24X48. Too big! Am thinking to build strawbale walls INSIDE up against existing walls - particularly the inside of walls to the outside, for insulation, aesthetics, quiet and to make it more snug. This is do-able, right? Can you make any suggestions?

A:(Owen Geiger) Yes, this can be done. You can stack bales flat or on their edges. Hold bales in place by tacking a nail in the wall (locate all studs first) and tying with some baling twine. Consider adding all new electrical. The areas over doors and windows can be built with mesh or plasterer's lath stuffed tightly with loose straw. Wear a dust mask and be extremely careful to prevent fire. I would cover bales with earth plaster. No mesh is necessary.

Q: Can flaxseed strawbales be used to build these homes?

A:(Owen Geiger) Yes, although I'm not familiar with flaxseed straw. The best, most durable straw is waxy. Look for dense, dry bales.

Q: My husband and I are building a large strawbale house and have completed most of the first coat of lime/earth plaster. It has now become clear that there are some places where it is very difficult to get a good seal of plaster - for example, between the top of the wall and the sloping ceiling, and around / behind switch boxes. The plaster seems to inevitably crack where there is a transition between types of surface. Is there anything we can use other than our lime/earth plaster to get a good seal at these difficult places? I'm thinking perhaps some kind of builders felt, or a lime slip? Any ideas welcome.

A:(Owen Geiger) There's always a way to seal things, it just depends on the details. I'd have to see a detail drawing or close up photo to give you a definitive answer. But in general you stuff straw or straw/clay behind outlets before mounting the boxes. If you missed that step, maybe you can take a stick or ruler and poke insulation around the box. Plaster will take care of the rest. The ceiling is trickier. This is where builders felt would help. You could place a bead of caulk and then apply the felt. Cover this with mesh and plaster and it shouldn't leak. It's called bridging dissimilar materials. Google that phrase and maybe you'll find more ideas.

Q: We are inexperienced, but have researched quite a bit. Something I stumbled across recently indicated that a way to avoid mold in colder climates was the use of earthen plaster on the outside walls. Since warm air leaks out to the cold, if there is a moisture-proof barrier, the air & moisture get trapped inside and then the straw can rot. When a clay-dip is used with earthen plaster on both the inside and outside walls, there was minimal mold.

A:(Owen Geiger) That should help, yes. But I would use wide roof overhangs and a high quality roof that won't leak for many years. Also, drape some plastic over the very top of the wall so any roof leaks would run down the face and be noticeable.

Q: I have an almost complete straw bale building (small studio in garden). The outside has been lime rendered / washed. The inside is ready to be rendered / plastered but have been waiting for door and window to be fitted before starting due to winter. I have now discovered that some of the bales have crumbled away forming fairly large cavities on the inside surface, maybe 1 to 2 dinner plates in area and, in places, half a bale deep. The building is still sound as 95% of the bales are OK. There are no signs of damp and all the bales were checked for moisture content before use. It may be foolhardy but I plan to repair the damage as best I can and continue with the building, as the thought (and cost) of lifting the roof and re-building the walls would just not be feasible right now. Would appreciate any comments, advice etc.

A: (Kelly) I suggest that you assess exactly why the bales have these cavities. Is it because critters have been digging there? Were the bales defective in the first place? Can you expect this problem to continue over time? If you feel that the bales will be substantially OK once they get plastered, then I think that somehow patching the damaged bales and finishing your structure is a reasonable approach.

Q: I am interested in building with straw bales. But, I want to use metal siding instead of stucco or clay etc. I have an idea about building 2x4 stud load bearing walls. Placing the straw bales up against the stud wall. This would leave a 3.5" gap from the bales to the outer wall. I would attach the metal siding to the outside of the studs. I have an idea I would incorporate a vented area at the top of the walls where the walls meet with the 3' eave over hangs. Do you think this would work to allow the straw bales to expel any moist and breath properly? I could also put some sort of Tyvek wrap between the metal siding and the studs which would eliminate any metal sweating that might occur from the siding.

A:(Owen Geiger) Stud framing/strawbale: This is what we did in Pueblo, Colorado for two out of three strawbale houses. We filled the stud space with insulation for improved R-value. We used OSB and wood siding on the outside. Others have used metal siding. Either way is okay.

(Kelly) I might add that your idea of providing a venting "rainscreen" effect with the metal siding is a good idea.

Q: I am nearing completion on a round wood framed circular strawbale home. The home has a good boot and hat except on its most vulnerable side (north) where rain has hit the exposed bales down low before I could lime plaster them. I've kept the questionable bales covered for the last 6 months with a free leaning metal sheet. I tested them yesterday and the highest reading I got was 20. If I lime plaster now will that help prevent further dampening and allow the bales to dry more in time?

A:(Owen Geiger) You're right on the upper limit of moisture content. You might just get by if you can dry it out. Have you tried placing a heater safely nearby and maybe a fan? In the future you'll want to extend the roof in this area so it doesn't happen again. The Last Straw Journal has extensive information on this topic, including how to replace bales and when. But it's scattered through different issues and may be hard to track down. One unknown issue is your local humidity. It may be difficult to get it dried out.

Q: I would like to build a barn with walls that are 15' tall, 55' long and 22' wide, with 2' over hangs. I want to build it with post and beam and use strawbale inset. Is it possible to make a wall this tall with strawbale?

A:(Owen Geiger) Yes, this is possible. Depending on the distance between posts, you'll probably need some pinning or supplemental bracing. For instance, you could lay some 1" thick boards flat between courses of bales every 5' in height. Use your judgement. Simply add some internal or exterior pinning using bamboo or willow saplings, or wooden braces like I just described. Add as needed when the wall starts to feel wobbly. I suggest using a gravel bag foundation to save thousands of dollars and speed construction.

Q: I built a small workshop. Load bearing, strawbale, clay and sand for plaster. It is small and not meant to stand forever so I experimented with just a dug out clay road mix foundation. It’s working great except that in the spring as the snow melts the bottom few inches sloughs off. I tried to patch it last year but it grabs the layer above and it sloughs off too. I don’t want to have to plaster the whole outside again. I know it’s the heavier bottom layer grabbing the light outside layer but it happens no matter how light I make it. Really confounded. Any suggestions?

A:(Owen Geiger) I would recommend weep screed placed about 12" off the ground to separate the earth plaster above and cement plaster below. Maybe you could cut the plaster, add the weep screed and put cement plaster on the bottom of the wall.

Q: I built a straw bale house two years ago. I hired a consultant, plastered the walls interior and exterior, and have a large roof overhang. All that said - when it is warm, I can smell straw. I have used a moisture meter in a dozen places and the walls are hovering between 8%-12%. I found one spot that was particularly vulnerable to moisture penetration that was 14%-15% but I have patched it and it is dropping as well. And yet I smell straw. Anybody had this problem or fixed this problem?

A: Smelling straw is not the same as smelling rotting straw. The moisture level readings you took are all reasonably good, within very acceptable tolerances. Smelling straw indicates to me that there are gaps in the plaster somewhere, probably at the bottom or top of the wall. Somewhere it's open and allowing the smell to escape, which is not necessarily mean the bales are wet. I'd also recommend that you take more moisture readings, specifically at the bottom of the walls, north, south, east and west. If there is condensation or excessive moisture, that is where it often concentrates. If there are moisture readings above 20% relative humidity, that could be a problem. It might mean there is capillary wicking from the ground, or condensation. If you find gaps in the plaster, best to close those gaps.

Q: We recently inherited our mother's straw bale house and need to repaint it. I remember she used a lime wash but I don't know what recipe to use to repaint the house; I also cannot find the book she referred to when she built the house 15 years ago. Any insight would be greatly appreciated.

A: You are right to seek out information about lime before "repainting" it. In essence a lime wash can be applied like paint to freshen up a lime-plastered wall, but for safety and long-term success with the procedure, it's wise to understand the material, not just follow a recipe. First off, lime can be dangerous to work with: As it's combined with water, the chemical reaction and resulting lime putty will burn bare skin -- so long sleeves, rubber gloves, and eye protection are a must while working with lime. There are several types of lime to choose from, each with different properties. A lime wash can be white, or contain pigments. It should be applied in several thin coats, each one thoroughly dry before the next is applied. Your climate will influence the drying/curing time; lime cures in the presence of moisture, so high humidity is preferred, and freezing weather can cause it to fail.

There is a long tradition of lime plastering in England, which would be a good source of educational material. And/or seek out a local person with expertise. If you want to do most of it yourself, an ideal arrangement might be to have an experienced practitioner instruct you in the process. Lime plaster is often chosen for straw-bale walls because of its high permeability, or what many call "breatheability". If moisture vapor finds its way into a straw-bale wall, a permeable plaster will allow the moisture to escape, rather than condense into liquid inside the wall, where it can instigate mold growth. Earth plaster is even more permeable than lime, but is more vulnerable to weathering. Cement-based stucco holds strong against wind and rain, but could possibly trap moisture in a wall. Lime plaster is an excellent combination of being permeable, while still being relatively weather resistant. Steer clear of conventional paint for your straw-bale house. Even water-based paints are too impermeable, and could create invisible moisture problems inside the walls that you only discover when you smell or see mold. Again, climate plays a big role in the potential for moisture problems in a straw-bale house. But with careful design and good detailing, successful straw-bale homes have been built all over the world.