Building Riceland

Page 3

Completing the Top of the Dome

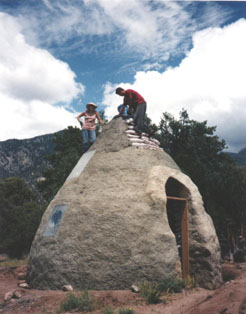

As you close in at the top of the dome, it becomes more necessary to

angle the folded end of the bag to adapt to the increasingly tight angle

of the circular course. This is fairly easily done just by arranging

the contents of the bag to make that angled shape. While working on

the conical top of the dome, one can actually climb around on the outside

like you would on a small mountain. Notice that I have kept the bottom

part of the dome tarped to keep off the sunlight, since it isn't plastered

yet.

As you close in at the top of the dome, it becomes more necessary to

angle the folded end of the bag to adapt to the increasingly tight angle

of the circular course. This is fairly easily done just by arranging

the contents of the bag to make that angled shape. While working on

the conical top of the dome, one can actually climb around on the outside

like you would on a small mountain. Notice that I have kept the bottom

part of the dome tarped to keep off the sunlight, since it isn't plastered

yet.

The Final Bags!

This view is looking up at the top of the completed dome from inside.

If you want to place an air vent here (which is a good idea), then those

last few bags can be moved over a bit to make room for it. I used 6 to

8 inch (15 to 20 cm) PVC pipe for this purpose, and then eventually use

a tether ball for a vent closure.

This view is looking up at the top of the completed dome from inside.

If you want to place an air vent here (which is a good idea), then those

last few bags can be moved over a bit to make room for it. I used 6 to

8 inch (15 to 20 cm) PVC pipe for this purpose, and then eventually use

a tether ball for a vent closure.

Releasing the Arch Form

Once the bags are stacked over the arch, then the form can be released.

As mentioned earlier, it helps to have the form shimmed into place so

that the shims can be easily knocked out to drop the form down and be

able to pull it out.

Once the bags are stacked over the arch, then the form can be released.

As mentioned earlier, it helps to have the form shimmed into place so

that the shims can be easily knocked out to drop the form down and be

able to pull it out.

Look Ma, No Form!

It is always amazingly pleasing to release the form and see the arch

standing all by itself.

It is always amazingly pleasing to release the form and see the arch

standing all by itself.

Applying Plaster

Finally the time has come to put plaster over the earthbags. This could

be done to some extent as you go along, but in many ways it is easier

to wait until all of the bag work is done, and do the plastering as

final step. We chose to experiment with papercrete (re-pulped paper

mixed with Portland cement and sand) as a plaster, and this has worked

out well, at least in our rather arid climate. The papercrete adds to

the insulation value of the wall. Other possible plaster materials for

the outside of the dome are common cement stucco and stabilized earthen

plasters. While the papercrete absorbs moisture like a sponge, the dampness

never migrates to the inside of the dome. Other plasters may require

that a moisture barrier (such as polyethylene sheeting) be draped over

the dome before applying the plaster, and then using a stucco netting

to reinforce the plaster.

Finally the time has come to put plaster over the earthbags. This could

be done to some extent as you go along, but in many ways it is easier

to wait until all of the bag work is done, and do the plastering as

final step. We chose to experiment with papercrete (re-pulped paper

mixed with Portland cement and sand) as a plaster, and this has worked

out well, at least in our rather arid climate. The papercrete adds to

the insulation value of the wall. Other possible plaster materials for

the outside of the dome are common cement stucco and stabilized earthen

plasters. While the papercrete absorbs moisture like a sponge, the dampness

never migrates to the inside of the dome. Other plasters may require

that a moisture barrier (such as polyethylene sheeting) be draped over

the dome before applying the plaster, and then using a stucco netting

to reinforce the plaster.

Working Around the Windows

Here I am plastering around one of the round windows, getting ready

to actually install the glass. Above the window you can see the ends

of the joists sticking through the bag wall, flush with the outside.

These wooden parts will be plastered over along with all of the bags.

In some cases, I put a wood preservative or sealing coat over the ends

of the wood, just to make sure that they don't absorb too much moisture

and tend to rot over time.

Here I am plastering around one of the round windows, getting ready

to actually install the glass. Above the window you can see the ends

of the joists sticking through the bag wall, flush with the outside.

These wooden parts will be plastered over along with all of the bags.

In some cases, I put a wood preservative or sealing coat over the ends

of the wood, just to make sure that they don't absorb too much moisture

and tend to rot over time.

Fitting the Glass

While the plaster is still wet, I placed the glass I intended to use

for the window over the opening and scored around the perimeter of it

with a trowel edge to indicate where the glass will need to fit. The

glass I used was obtained at glass shops as seconds or glass that they

wanted to sell cheaply because it was cut wrong or nobody picked it

up. Most of this was "thermalpane" (two layers of glass) for

better insulation. In some cases the seal between the panes allowed

moisture to enter the glass, but mostly these have held up OK.

While the plaster is still wet, I placed the glass I intended to use

for the window over the opening and scored around the perimeter of it

with a trowel edge to indicate where the glass will need to fit. The

glass I used was obtained at glass shops as seconds or glass that they

wanted to sell cheaply because it was cut wrong or nobody picked it

up. Most of this was "thermalpane" (two layers of glass) for

better insulation. In some cases the seal between the panes allowed

moisture to enter the glass, but mostly these have held up OK.

Preparing the Plaster to Accept the Glass

Using the score line, I remove enough of the wet plaster to be able to

recess the glass into this cavity. It may take several times of placing

the glass there to make sure of a good fit. Once you are satisfied that

the glass will fit, you can let the plaster set up before actually installing

the glass; this will give the glass a firm base to sit on. With Riceland,

I did two applications of plaster, so that when I did the second coat,

I overlapped the glass with the new plaster on the top and on the two

sides. The bottom was left flush with the original coat so that water

would run off...sort of like shingles are set.

Using the score line, I remove enough of the wet plaster to be able to

recess the glass into this cavity. It may take several times of placing

the glass there to make sure of a good fit. Once you are satisfied that

the glass will fit, you can let the plaster set up before actually installing

the glass; this will give the glass a firm base to sit on. With Riceland,

I did two applications of plaster, so that when I did the second coat,

I overlapped the glass with the new plaster on the top and on the two

sides. The bottom was left flush with the original coat so that water

would run off...sort of like shingles are set.

Finishing the First Plaster Coat

Plastering is an activity where help is always welcome. It doesn't

take much experience to be able to do it, and it can be a fun social

affair.

Plastering is an activity where help is always welcome. It doesn't

take much experience to be able to do it, and it can be a fun social

affair.

Vents and Completed Window

Here you can see the air vent at the top, complete with its bonnet to

keep rain from entering. This can also be screened to keep insects from

coming in. A stainless steel insulated wood stove vent is below the top

vent. Also you can see how the final coat of plaster overlaps the window

to shed water. Inlet air vents can be arranged strategically at lower

levels...this should be done while the building is in progress.

Here you can see the air vent at the top, complete with its bonnet to

keep rain from entering. This can also be screened to keep insects from

coming in. A stainless steel insulated wood stove vent is below the top

vent. Also you can see how the final coat of plaster overlaps the window

to shed water. Inlet air vents can be arranged strategically at lower

levels...this should be done while the building is in progress.

Completed Dome!

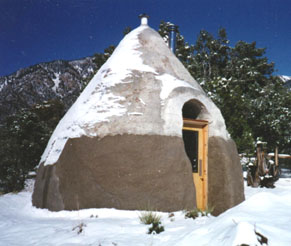

We started building Riceland during the summer, and by

the time the snow was flying it was snug and cozy inside.

We started building Riceland during the summer, and by

the time the snow was flying it was snug and cozy inside.

Adding Color

A final color coat can be applied, either by using conventional cement

stucco methods, or by painting the plaster. I used a pigmented lime wash

stabalized with latex on the papercrete at the left.

A final color coat can be applied, either by using conventional cement

stucco methods, or by painting the plaster. I used a pigmented lime wash

stabalized with latex on the papercrete at the left.

The pictures below show me and my wife Rosana standing in the doorway of Riceland, and me celebrating on top of it.

For Email contact go to About Us

Established in 2001, GreenHomeBuilding.com is primarily a labor of love. Kelly, and the GreenHomeBuilding team of experts, have answered thousands of questions for readers over the years, and we continue to publish up-to-date information about increasingly important sustainable architecture. If you feel moved to assist us in this work, your kind donation would be much appreciated; this can be easily done through our PayPal account:

VISIT OUR OTHER WEBSITES:

[Natural Building Blog] [Earthbag Building] [Dream Green Homes]

Disclaimer Of Liability And Warranty

I specifically disclaim any warranty, either expressed or implied, concerning the information on these pages. Neither I nor any of the advisor/consultants associated with this site will have liability for loss, damage, or injury, resulting from the use of any information found on this, or any other page at this site. Kelly Hart, Hartworks LLC.