Cast Earth

Cast Earth is the invention of Harris Lowenhaupt of Phoenix, Arizona. He grew up in an adobe home in the Southwest and loved the feeling of living in an earthen home. As a chemist he became fascinated with the idea of making earthen homes castable. Instead of making individual adobe blocks for building, or intensively ramming earth into forms little by little, he wanted to be able to just pour the plastic earthen material into a form and have it set up very quickly, within a day!

He

started experimenting with adding calcined gypsum (plaster of paris)

to earth, and found that a fairly small percentage (about 15%) of the

gypsum would make a very solid block. This worked fine for very small

projects, but for larger walls it set up way too quickly (within minutes)

to be practical. So he looked for retarding agents that could be added

to the mix to slow down the setup time. Standard retarding agents would

only expand the time frame by a few more minutes, so he needed to look

beyond conventional practice.

He

started experimenting with adding calcined gypsum (plaster of paris)

to earth, and found that a fairly small percentage (about 15%) of the

gypsum would make a very solid block. This worked fine for very small

projects, but for larger walls it set up way too quickly (within minutes)

to be practical. So he looked for retarding agents that could be added

to the mix to slow down the setup time. Standard retarding agents would

only expand the time frame by a few more minutes, so he needed to look

beyond conventional practice.

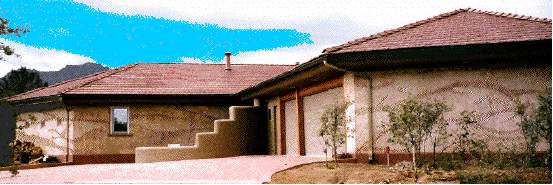

In the early 1990's, Harris came up with a promising mix that allowed about two hours of working time and he build his first prototype building using this method in 1995. Since then he has refined the process to allow setup times of over eight hours, which makes possible very large scale building projects.

Cast Earth has some very interesting and useful properties. The

compressive strength is about the same as adobe or rammed earth, sufficient

to support most conventional building loads. The tensile strength, however,

is several times greater than these materials, which makes it much stronger

and perhaps more durable. Unlike adobe, Cast Earth does not shrink as

it cures (it actually expands slightly), making it much less likely

to crack. Like other earthen materials, it will absorb moisture, but

it retains enough strength, even when saturated, to maintain its structural

integrity. It can be rendered moisture resistant by the use of additives

to the original mix, or by spraying the finished product with a silicon

spray.

Another

major consideration is that Cast Earth can be made from a wide variety

of types of soil. Unlike Adobe, rammed earth, and cob (which must have

a certain ratio of clay to larger aggregate soil), Cast Earth does not

require the binding capacity of clay. It can utilize soil with some

clay in it, but this is not necessary. And unlike cement, which cannot

tolerate much fine material like clay, Cast Earth can easily incorporate

it into the matrix it creates.

Another

major consideration is that Cast Earth can be made from a wide variety

of types of soil. Unlike Adobe, rammed earth, and cob (which must have

a certain ratio of clay to larger aggregate soil), Cast Earth does not

require the binding capacity of clay. It can utilize soil with some

clay in it, but this is not necessary. And unlike cement, which cannot

tolerate much fine material like clay, Cast Earth can easily incorporate

it into the matrix it creates.

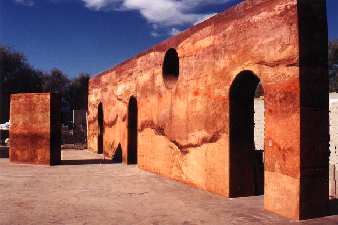

I

think that one of the most significant aspects of this new material

is aesthetic; the completely natural, variegated appearance of the finished

wall that has not otherwise been covered is stunning. It resembles cut

sandstone slabs, with random patterns of striations that swirl throughout

the surface. This fact alone makes it worth considering for your building

project.

I

think that one of the most significant aspects of this new material

is aesthetic; the completely natural, variegated appearance of the finished

wall that has not otherwise been covered is stunning. It resembles cut

sandstone slabs, with random patterns of striations that swirl throughout

the surface. This fact alone makes it worth considering for your building

project.

The

thermal properties of cast earth are similar to other earthen materials:

it makes for excellent thermal mass, but has little value as an insulator,

except that because the walls are generally quite thick, and it takes

many hours for atmospheric temperatures to approach the interior portions

of the wall. For this reason it would be best to provide some insulation

in the wall system where extremes of temperature are found. This can

be accomplished with exterior insulation, as would be done with rammed

earth, or it is also possible to imbed the insulation within the wall

at the time of pouring, as shown at the left.

The

thermal properties of cast earth are similar to other earthen materials:

it makes for excellent thermal mass, but has little value as an insulator,

except that because the walls are generally quite thick, and it takes

many hours for atmospheric temperatures to approach the interior portions

of the wall. For this reason it would be best to provide some insulation

in the wall system where extremes of temperature are found. This can

be accomplished with exterior insulation, as would be done with rammed

earth, or it is also possible to imbed the insulation within the wall

at the time of pouring, as shown at the left.

The fact that the process for making Cast Earth has a patent pending

might discourage some folks from getting involved. I can understand

this; I prefer to work with materials and processes that have no strings

attached. However, in this case, Harris is willing to provide training

to those who are are really interested, and the nature of the process

itself demands the use of a lot of heavy, mechanized equipment which

is best handled by people who are familiar with the process. There are

currently several contractors who are licensed to do this work, and

over time there will be more.

All of the photos shown here are courtesy of Cast Earth.

Frankel Salisbury Home this page is very image intensive and takes forever to load, but it shows this architect's home, which uses quite a bit of Cast Earth, under construction.

Soil Cement

A variation of Cast Earth that has been around since cement was first formulated is Soil Cement. This is really just ordinary concrete with the sand/gravel aggregate replaced by soil. This especially works well with rather sandy soil, but will also work with other soil types. The heavier soils with more clay content will probably require more portland cement. Soil cement has been used to form walls, make floors, pave roads, stabilize river banks, etc.

Here is some information about formulas: Make it by mixing earth with Portland cement to the desired depth, add water and mix again. Tamp, and cover with plastic to let it cure properly. Use 6 to 16 percent cement by volume according to the density of the soil. The denser the soil (clay, for instance), the higher percentage of cement to use. Six percent translates to 1 part cement to 15 parts soil; 16 percent translates to 1 part cement to 6 parts soil.

solarsensedesigns.com has a very informative description of making and forming soil cement projects.

Soil Cement Construction Handbook

by Portland Cement Association, 1995

For Email contact go to About Us

Established in 2001, GreenHomeBuilding.com is primarily a labor of love. Kelly, and the GreenHomeBuilding team of experts, have answered thousands of questions for readers over the years, and we continue to publish up-to-date information about increasingly important sustainable architecture. If you feel moved to assist us in this work, your kind donation would be much appreciated; this can be easily done through our PayPal account:

VISIT OUR OTHER WEBSITES:

[Natural Building Blog] [Earthbag Building] [Dream Green Homes]

Disclaimer Of Liability And Warranty

I specifically disclaim any warranty, either expressed or implied, concerning the information on these pages. Neither I nor any of the advisor/consultants associated with this site will have liability for loss, damage, or injury, resulting from the use of any information found on this, or any other page at this site. Kelly Hart, Hartworks LLC.